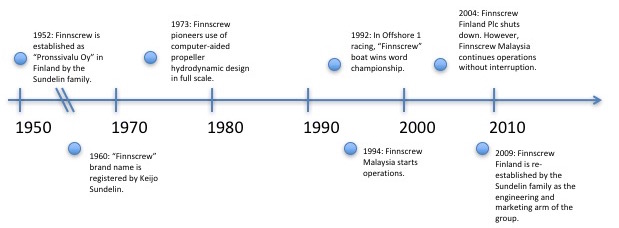

Finnscrew has always been at the forefront of technology

Originally established in 1952 as "Pronssivalu Oy", Finnscrew has always been pushing the forefront in

both manufacturing foundry technology and propulsion design and engineering. We have always been early

adopters of the most significant advances in the field, like using computers for operational design and engineering.

Our proprietary system for propeller pattern manufacture and casting, originally developed in 1970's,

is still unrivalled in the industry today.

The early years (1952-1959)

Finnscrew started originally from very humble origins. In 1952, the entrepreneurial-spirited Sundelin

family decided to establish a new foundry business in Vanaja, a small community in southern Finland.

The initial business idea was to provide brass and bronze castings for the Finnish industry - the original customers

ranging from paper & pulp industry to civil engineering.

Entering the marine market (1960-1969)

In 1960 "Finnscrew Works" was registered as an auxiliary name of the company, to tackle the emerging

business in boat and ship propellers.

In the latter part of the decade, Hollming Works in Rauma started to manufacture its now famous range

of Azimuth thrusters, and Finnscrew was chosen to be the primary supplier for propellers.

Advent of the computer age (1970-1979)

In the early seventies, Finnscrew decided to make a major investment to computerise the propeller

design. At the time, the commonly used methods for propeller selection were based on mostly graphical

methods utilising experimental curves. Earliest methods to enable computerised design were

developed in late 50's, but at the time they were not ready for production use. The advent of

minicomputers in the late 60's opened up completely new possibilities to make advanced computer-aided design

and engineering a major part of the normal propeller delivery process.

Finnscrew commissioned Dr Max Honkanen from the Helsinki University of Technology to design such

a program, on a Wang 2200B minicomputer. The programs were very advanced at time, utilising the

lifting-line theory still commonly used today. However using computers of the period was rather challenging, as the

device had at best 16Kb of memory and a cassette tape drive. In the latter part of the decade

the computer was naturally upgraded to a newer model of the Wang 2200 MVP type, and calculation

time reduced from 45 minutes to 5 minutes. Early on, also more advanced features like lifting-surface

corrections and cavitation prediction were included in the design software suite.

The usage of computers was not limited to just design - Finnscrew also developed at the time

its proprietary computer-aided pattern making process, enabling minimised working allowances and

maximum material cost savings. Finnscrew also increased its capacity and client base, and moved its

factory to nearby town of Turenki.

Going international (1980-1990)

The eighties were a time of internationalisation for Finnscrew. Agencies were set up around Europe, in

countries like Sweden, Norway, Italy, Germany and Spain. Finnscrew become a household name in its

main markets in Europe, associated with comcepts like performance and quality.

On computerization front, major advances were also made. Design system moved to Hewlett-Packard

HP9000 system, and much more advanced design methods were now possible. This generation of

software still forms the basis of the Finnscrew propeller design practice today.

Interesting projects of the period include the design of propellers for both main propeller and maneuvering

thrusters for the MIR submarines. The main propeller and nozzle were manufactured of a special composite

material developed specifically to this purpose. Operated by the Russian Science Academy and built in Finland,

they are among the very few craft in the world capable of diving to depths in excess of 20 000ft.

Racing for victory (1991-1994)

In 1991, Finnscrew decided to be the main sponsor of a Offhore-1 boat racing team. The "Finnscrew" boat

was a twin-engined aluminum catamaran , capable of over 100kn speed. The boat was driven by Finnish

businessman JP Mattila and Italian Walter Ragazzi. Later in the second season of competition in 1992,

the "Finnscrew" boat won the world championship in Dubai - an event that was televised over the world,

giving extraordinary visibility for the Finnscrew brand.

At the time, Finnscrew also ventured into a new business - the unique robotic grinding technology

developed in-house by Finnscrew jointly with the Finnish academia, was spun-off to a new company -

Robotic Techology Systems Plc (RTS).

Age of expansion (1994-2005)

Finnscrew Malaysia Sdn Bhd was establised in 1994 as a second manufacturing facility to tackle especially

the Asian marketplace.

- In 1997, Finnscrew exits the RTS spinoff, which enables it to expand to a new foundry facility in

Lahti, Finland. - In 1999, Finnscrew expanded its equity to a foreign investor, which was to bring new business

opportunity and large orders. - However, the dual sites in Turenki & Lahti were bound to be united. In 2000, it was decided that

the foundries were to be united in a single new facility in Turenki, enabling manufacture of

larger propellers than ever. - In 2005, Finnscrew Finland Plc ends its operations, ending a major chapter in the Finnish

marine industry history.

Re-emergence in Europe (2009-)

In 2009, Keijo & Henri Sundelin established a new company, Finnscrew Finland Oy, for Finnscrew

to take back its rightful place in the global marine market. Backed by the manufacturing expertise of

Finnscrew Malaysia, we can provide competitive high-quality products for the global marine

marketplace.